Its up ,listen out for me #on air guys

My trials and tribulations

Hi all ,this blog is going to show some of the tricks in my life ,Enjoy !

Sunday 31 August 2014

Up up up and away

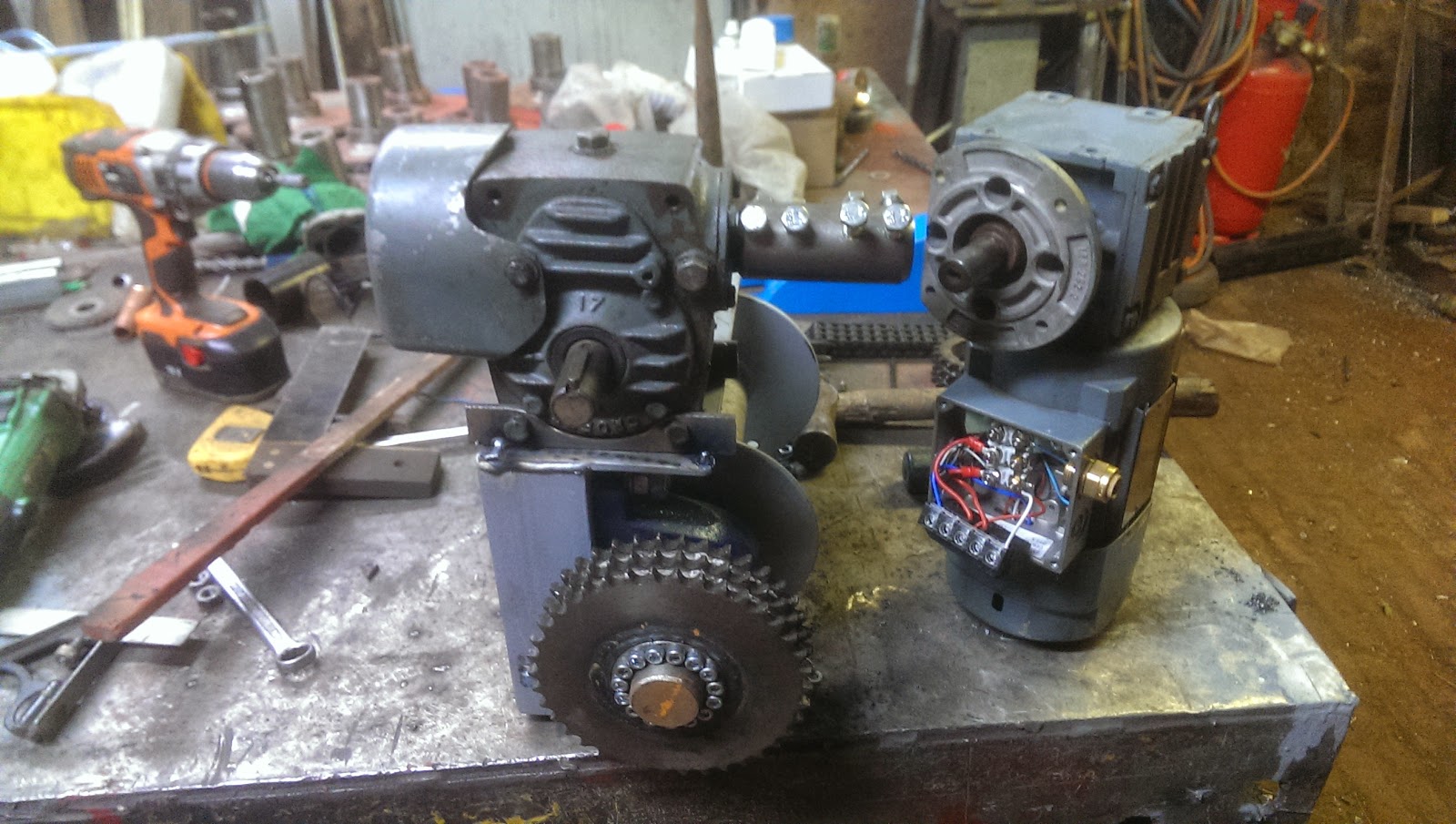

New Gear box all in place and in its mounts .Pad at the side is for the tourqe reaction arm just to allow a little movement in case the coupling isn't bang on !

Managed to maintain the old chain guard ..saved a bit of time there .

Motor fitted to final drive with anchor arm in place

From the other side

Saturday 30 August 2014

Its too fast

Got round to trying the #electric tower winch ..if the motor had got enough poke it would of been up in 10 secs .It needs a reduction .Just so happens I've got the one left which I didn't use from the rotator :-).

By mounting the box here, if its still to fast i can put another chain reduction on it LOL .It will do 3 rpm as oppose 30 before .

By mounting the box here, if its still to fast i can put another chain reduction on it LOL .It will do 3 rpm as oppose 30 before .

Of course its never all straight forward over here ...the box is imperial ,they don't do metric imperial motor couplers so ive made one ...yes yes ill get some grub screws ,but for the time being they will suffice. These will also provide the drive (cant cut internal keyways here ) being as they are on the low torque side it should be fine if they break ,the worm drive will hold the tower up .

A bit more tomorrow

Saturday 9 August 2014

A lick of paint

All Painted ,Ringspan tightened ready to roll

Installed onto tower, this nearly killed me !!! One hell of a lift with a bad back ,anyway its there !!!

View from the other side

What's left to do now is get a bag of volts and chuck it in the motor ....maybe tomorrow i'm beat and need a seat .....oooh it rhymes .

Friday 8 August 2014

Back to the winch (raise and lower)

Back to the winch .Having fitted the triplex chain ,it really needs a guard on it !!

Off cut of 3mm from the workshop steel archive !! cut and shaped

Welded a band around the 2 half's then cut through middle ,makes a clamshell guard

This will keep the weather off the chain ,also keep the kids from getting there fingers in it ,having said that the winch is in the air abt 6ft/1.8m

A lick of paint is all i need to finish this now,unfortunately im struggling with a bad back and retired from workshop duty for a bit

Saturday 19 July 2014

Rotator install

A rush to beat the rain with the install ...but its up there ,however the rain beat us to the mark so still have the cable to install to the house :-(

What a thunder storm ,constant lightning ...eyes fixed on top of mast !!!

Fitted a new stub mast too at 6m ,however im not happy with it it's 52 mm 6mm wall aluminum i recon 65mm will stop the sway a little .

Friday 18 July 2014

Sunday 6 July 2014

Fitting rotary encoder

Fitting of rotary encoder ,all that had to be done here is turn an adapter down to fasten and centralise the encoder

Its in ,I need a holding bracket but ran out of time,today

Friday 4 July 2014

Rotating tube clamp

Boss had to be turned then welded to tube.Tightly sleeves over the landrover UJ and welded.I also drilled a hole in bottom of UJ to let the water out ,any trapped water in the winter can do some serious damage when frozen.

After Welding

Studs welded to take up slack on rotating pole.Inside the tube is 68mm,pipe will be 65mm ,so a little play .

Bottom is drilled to put a drive dowel through the pole.Bit of cold galv and i recon the top is done .

What's left to do know is mount the rotary encoder on the base of output shaft ...and i'm good to go !!!

Saturday 28 June 2014

Rotor controller interface

Rotor controller and pc interface ,running K3NG software and M0UPU shield for the arduino.Easy to put together just a plug in affair .Longest job was cutting the hole for the lcd display .This is just the interface for the pc the relays and 24v supply will be at base of tower ...well thats the idea for the moment !!

Rotor output shaft

Here's the output shaft for the rotator 40mm round bar turned down to 25mm then a plate welded on ,faced off then recessed for the universal joint (EX Landrover of course)

Will it fit .....oh yes

Boss to fit on top of UJ and carry antenna pole

Saturday 7 June 2014

Rotator

Ok I got the tower up ,antenna on top ,but at the moment its fixed stateside .I need to turn it !!.cue drum roll.

.....Thats right its rotator time.Price of new ones are in the range of £1500 to £2000 with this kind of spec.Clearly im not going to pay that so here we are again in the workshop putting together a nice new one.

Motor is from a motorised invalid scooter they are on ebay Parvalux do one with reduction for around £30 ,not sure how long the price will last as it seems cheap to me !!Gearbox is a ....chinese one from the uk importer ,50:1 reduction worm drive price £79.

Right upto the hilt ,picture from above motor/gb fitted ,we need adapter/torque reaction plate

Need a bottom flange to mount to the tower ..same footprint as the yaesu rotator and a shaft through the middle to fasten to the antenna pole to rotate it ...maybe tomorrow ???

.....Thats right its rotator time.Price of new ones are in the range of £1500 to £2000 with this kind of spec.Clearly im not going to pay that so here we are again in the workshop putting together a nice new one.

Motor is from a motorised invalid scooter they are on ebay Parvalux do one with reduction for around £30 ,not sure how long the price will last as it seems cheap to me !!Gearbox is a ....chinese one from the uk importer ,50:1 reduction worm drive price £79.

Output shaft on motor/gb is 12mm ,worm drive box input shaft is 14mm ..so we need a bush ,10 mins on lathe ,you can see it in the pic .

Motor/gb fits real snug into worm drive input shaft

Right upto the hilt ,picture from above motor/gb fitted ,we need adapter/torque reaction plate

Adapter plate for motor to gb

Adapter plate fitted to motor

Motor/gb fitted to worm drive

Next is the base to tower connection ,this will also house the rotary encoder .Made with 316 stainless and 304, weld looks a little rough ....i didn't have any dissimilar rods left for the tig so a quick look in the stores and fortunately i had some 312 rods ,knocked the flux off and there ya go !!!

Friday 6 June 2014

Electric tower winch on original versatower mount

Motor is now mounted ,a further reduction though sprocket and chain

All tacked together,ready for welding up .The three holes at the back bolt to original hand winch mount.Fabrication wise all i need now is a chain guard.

Thursday 5 June 2014

For the idle cranker ...electric winch

Here we are again .Winding the tower up and down sucks ,so here's the solution .Basically what we have here is a bit of 50mm bar with some 5 mm plate bored and welded on for the side plates .Having some 40 mm bearings left over from a job means there the first port of call so the shaft is turned down to take them.

Almost finished cable drum need's to be drilled through side plate to hold the wire.The right hand extension will have a sprocket on a taper lock fitted this will be driven from a gearbox reduction with inverter for soft start ...happy days ...well nearly ....i can see the light !!!

Sunday 1 June 2014

Tower parts all back from the galvanizers,lower extension slid into base of old tower

End welded on galvafroid over the weld joints.Re-roped ready to go

Base put into place with trusty jcb ...bless it ,base comes in at 3/4 tonne .Bolted down with 8 x22mm bolts.Here she is sat on the base .

First tilt over ,had a bit of a boo boo here the rope wasn't long enough duh!! came from original tower the arc was far smaller ,minor alteration from 3 falls to 2 ...its now long enough .Its 10mm rope and now has a better leverage over load (with lower extension) so will be ok !!!!

Antenna fitting went easy

Clamp up mechanism and new stainless rope sheath ... lost the original one so knocked another up .

You can see here the rope route through tower and various pulleys..works great

Elements need a little leveling up ,will sort it out later .Was a bit of a struggle putting it up on my own :-(

Subscribe to:

Posts (Atom)